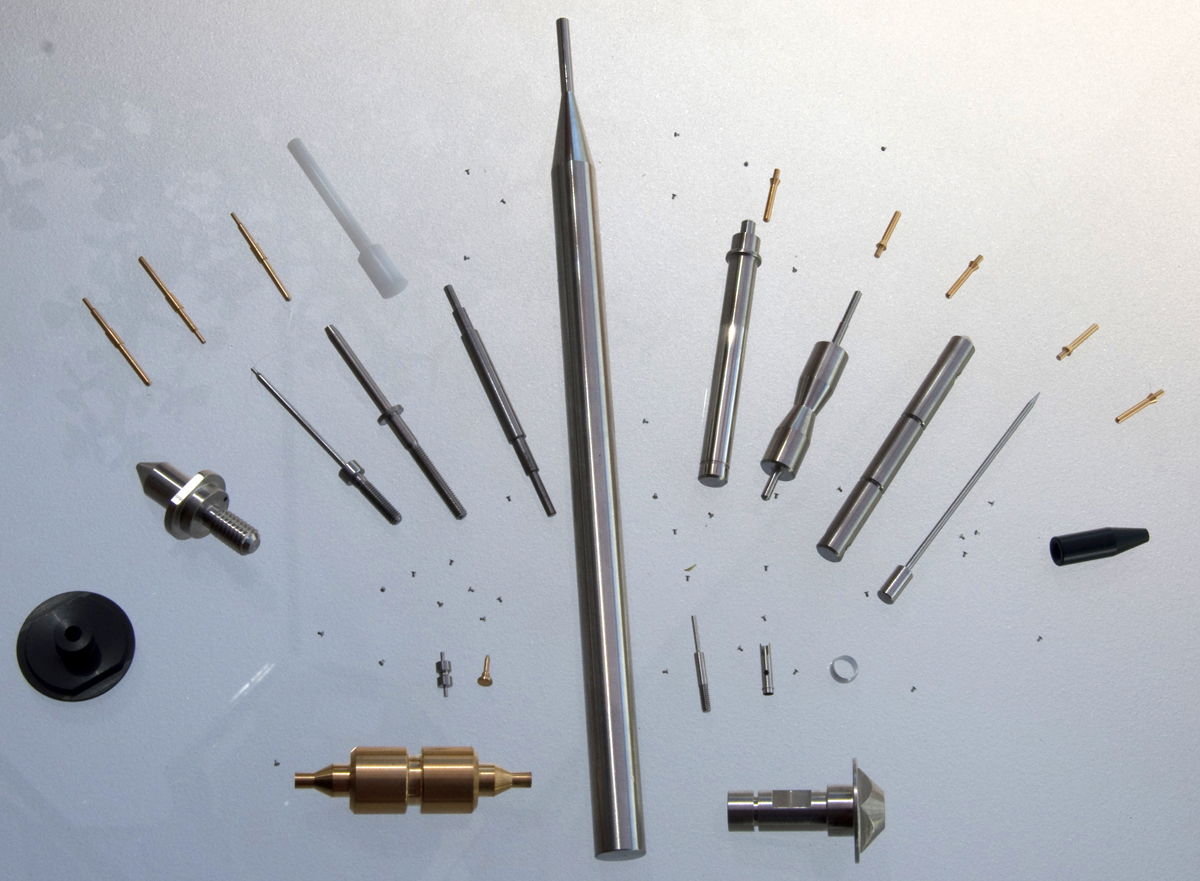

- Precision engineering turned parts on a sub-contract basis.

- Modern multi-axis CNC sliding head machines with sub-spindle and milling capability, with "lights out" production to reduce costs.

- Microscopic parts (from less than 1mm

diameter up to 20mm diameter maximum).

- Wide range of stainless steel, ferrous, non-ferrous and plastic materials machined to order.

- From small prototype batches up to high volume production runs.

Machine Capability Chart

MACHINE

CAPACITY

DESCRIPTION

SUITABLE FOR

Star SR10J

Star SR-20R (x2)

Star SA-16

Star SB-16E

Star SV12

Star SA16-RC

10mm

20mm

16mm

16mm

12mm

16mm

All CNC Sliding Head Production Lathes with magazine bar feed & sub-spindle, Live cross-milling & drilling & tapping

JBS Autocompensation Guide Bush Systems have been fitted to the majority of our Star CNC Lathes. This clever device automatically compensates for variation in barstock diameter and allows us to use standard bar tolerances, even on aluminium and plastics, without the need for the bar to be precision ground prior to machining, saving time and expense

Prototype and high volume production runs.

Complex slender parts.

Mitutoyo

Shadowgraph

PJ300

Precision optical measuring device,

complete with digital measurement

Measuring work pieces to

a very high standard

Meiji

Stereo Bench Magnifier

EMZ

Zoom Stereo Microscope

Quality Inspection Capabilities

Magnification 7x - 45x

Mantis Elite

Stereo Inspection Magnifier

Stereo Viewing System

Wide range of magnification options (to x20)

Long working distances; large depths of field

Shadow-free true colour LED illumination

Swift Video

Measuring System

2-axis video measuring systems, ideal for measuring 2-D features of small, intricate parts

Option of combined video and microscope measurement technologies

Colchester

Master Centre Lathe

6" x 24"

Manual Centre Lathe,

with digital readout on 2 axis

1 off and small batches of turned parts

Bridgeport Mill (x2)

Table size

48" x 9"

Manual milling machine with

Digital Readout, variable

speeds

General milling, prototype components and toolmaking.

We also have a wide range of NAMAS calibrated and traceable gauges for component qualification throughout the manufacturing process.